Support clip Nova Grip Steel C45, hot-dip galvanised

Support clip Nova Grip MTH steel hot dip galv.

SPRTCLIP-NOGR-STDD-(TZN)-M16

Register now and access more than 125,000 products

Used to establish force-transmitting connection between intersecting supports of different shapes and dimensions

Connection of superimposed supports also possible with identical flange widths

For equalising different flange thicknesses, up to three spacers with a total thickness of max. 15 mm, can be additionally placed between the support clips and connecting plates.

For type M12-LAS, height equalisation of two additional spacers (compared to standard type) is integrated.

- DIBt National technical approval Z-14.4-493

- Support clips M8 type standard and M12 type LAS without DIBt National technical approval

Datasheets(X)

CAD data (available after login)

- DIBt National technical approval no. Z-14.4-493 for support clips governs support clip connections for static, effectively static and dynamic actions

- Screws and support clips that have already been subjected to dynamic action may not be reused

- Design values of load capacity and threshold tensile force per clamped connection are described in DIBt National technical approval no. Z-14.4-493

For fixing connection elements, an assembly plate (strength class S235 or higher/plate thickness of at least 10 mm) is positioned between the supports to be connected.

Details of the respective plate dimensions and hole distances are indicated in general construction permit no. Z-14.4-493.

Screw fittings according to DIN EN 14399-1 or DIN EN 15048-1 consisting of hexagonal screws of strength class 8.8 or 10.9, nuts of strength class 8 or 10 and associated washers with a minimum hardness of 100 HV must be used, whereby for fittings of strength class 10.9 two washers are to be placed beneath the nuts in each instance.

| |

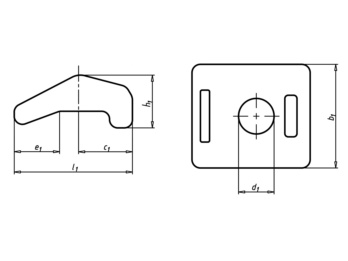

Suitable for screw | M16 |

Diameter of hole (d1) | 17 mm |

Length (l1) | 57 mm |

Width (b1) | 50 mm |

Height (h1) | 30 mm |

Nose length (e1) | 22 mm |

Distance from end of terminal to the middle of the drill hole (c1) | 25 mm |

Clamp height range (G) | -7 to 17 mm |

Material | Unalloyed steel, C45 |

Surface | Hot dip galvanized |

RoHS-compliant | Yes |

Conditions for tightening torque | See approval |

Tightening torque for property class 8.8 | 160 Nm |

Tightening torque for property class 10.9 | 160 Nm |

Type description | Standard |