For detailed information, other images and documents, please select individual articles from the following table.

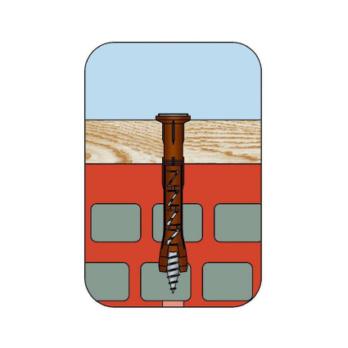

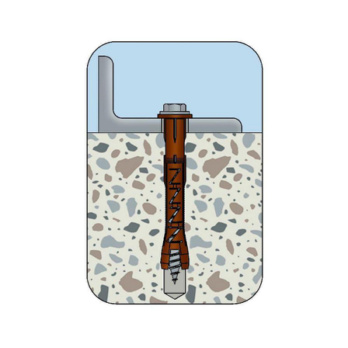

W-UR 14 F SymCon® plastic frame fixing with zinc plated steel hexagon head bolt, flat collar and SymCon thread

Special anchor geometry and immediate load-bearing capacity with ETA assessment for high loads for masonry, autoclaved aerated concrete and concrete

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Reliable and quick

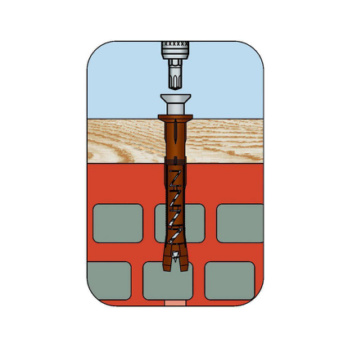

- Reliable follow-up expansion capability due to ingenious anchor geometry

- The teeth expand in four directions and claw into the base material

- Anchorage via friction locking between anchor sleeve and base material

- High loads due to expansion in four directions

- Improved load transmission through even, continuous load transfer across the entire expansion area

- Virtually no spinning of the anchor sleeve due to low installation torque and expansion

- Anchor sleeve made of high-quality polyamide

- Very strong anti-rotation lock

- Does not require an additional U-washer and prevents contact corrosion

Intuitive installation

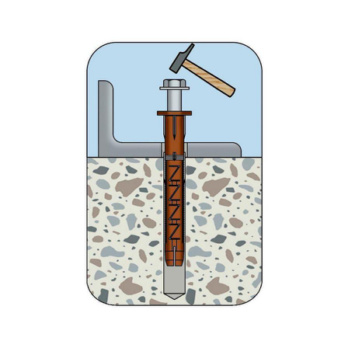

- Time savings due to immediate load-bearing capacity

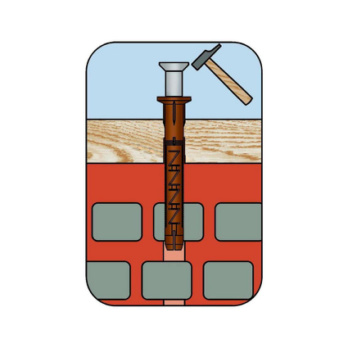

- Minimal installation work because the anchor sleeve and special screw are pre-assembled

- Hammer-in stop prevents premature expansion of the anchor during installation

Multiple embedment depths

- Masonry: Two embedment depths (50 and 70 mm)

- Concrete: Three embedment depths (40, 50 and 70 mm)

European Technical Approval ETA-11/0309, multiple attachment of non-load-bearing systems in concrete and masonry

- When anchoring in solid brick and solid sand-lime block, we recommend performing pull-out tests due to differences in brick manufacturing

- Lengths 330, 360 and 390 mm are not pre-assembled

Metal substructures

Metal substructures

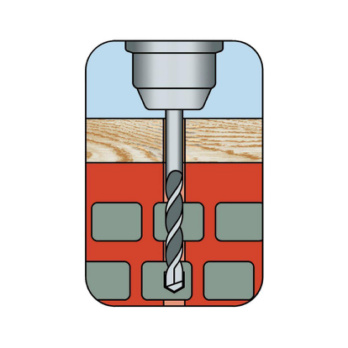

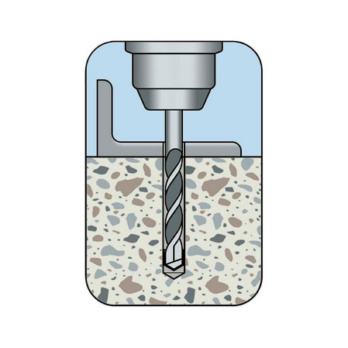

Create the drill hole

Create the drill hole

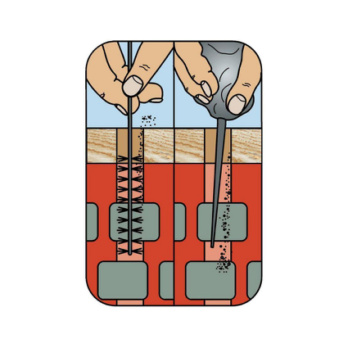

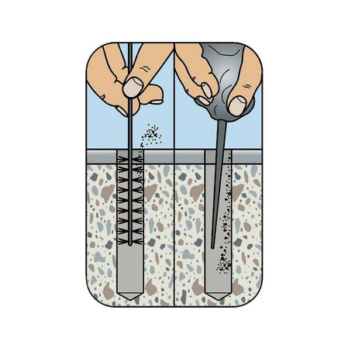

Clean the drill hole

Clean the drill hole

Set anchor and screw

Screw in the screw

Screw in screw until flush

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

Set anchor and screw

Set anchor and screw

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

European Technical Approval ETA-11/0309, multiple attachment of non-load-bearing systems in concrete and masonry

- Suitable for fastening façades, suspended ceilings, roof substructures made of wood or steel, wooden beams, wooden laths, angle brackets, wall-mounted cabinets, shelves etc.

- Suitable for anchoring in normal weight concrete masonry walls such as solid brick, solid sand-lime blocks, vertically perforated brick, hollow sand-lime blocks, hollow lightweight concrete blocks, solid lightweight concrete blocks, concrete bricks

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

- Drill cuttings must be removed from the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!